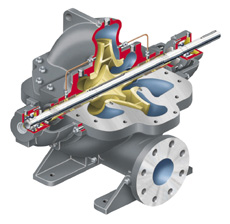

Split Case Pump Repair & Troubleshooting Guide

The split case pump can be taken apart and repaired on the job site or at the pump repair shop. Most of the time the top of the split case will be removed and then the pump shaft and the impeller will be taken out from inside the pump housing to be brought back to the pump repair machine shop so that the shaft and the impeller can be re-built.

If you are having trouble with your split case pump or you just have some leaks or some repair you can try a few things or alternatively call a professional pump repair company to do the work for you or your company (sub contract it out). The most common leaks that you will find on a split case pump is from the packing on the shaft of the pump. The packing is placed between the case of the pump and the pump shaft. Another common problem with the split case pump is the shaft coupling will be out of line and the pump and the electric motor that drives the split case pump will have to be aligned. Usually when the pump shaft is due for an alignment, its also a good idea to replace the spider grommet inside of the shaft coupling.

Pump Repair Companies can come to your location or job site and rebuild and troubleshoot the pump to get it working again. If you think you or your company can handle the repair yourself then you will need a few tools to get the job done. To take apart the split case pump you will need a large set of open end wrenches, a large set of impact sockets, a hammer, and also a come a long with a tripod.

How To Remove The Split Case Pump Shaft

The first thing you will want to do is to make sure that the power is just down to the motor connected to the split case pump motor coupling. once the power is off you can loosen the pump coupling on the motor and the pump shaft until the spider grommet can be removed and the two couplings are clear of each other. Now you want to make sure that the water supply and the discharge gate valves are in the off position so you will have no liquids flowing while your removing the top half of the pump. Once the supply and the discharge sides are closed you can get an impact socket or a large open end wrench and remove all of the bolts that go through the top and the bottom of the pump casing.

After you have removed all of the pump cover bolts you will want to remove the packing flange bolts at each end of the pump shaft. Be sure not to loose the pump packing flanges. You will need these when you install the pump shaft after removing it and have it rebuilt. Once you have removed all of the pump cover bolts you can pry off the top of the pump cover with a large pry bar and hammer. Once the pump cover gasket seal has been broken and the pump cover can be separated you can now hoist the cover out of the way with the come a long and the tripod.Now that the cover is off of the top of the split case pump you can remove the pump shaft and the impeller and bring it back to your pump shop or to another pump repair shop that can rebuild the shaft and the impeller. Most of the time the shaft bearings and the packing is replaced on the shaft. In extreme cases the impeller and the actual pump shaft will need to be replaced or possibly just repaired if there is not to much damage.

It’s impressive that you are getting ideas from this article as well as

from our argument made here.