Polaris Booster Pump Troubleshooting & Repair Guide

The Polaris booster pump is the driving engine for the Polaris pool cleaner. The booster pump provides a higher pressure then the swimming pool pump can so it can drive the Polaris cleaning unit. From time to time your booster pump will need some repairs or could have a problems that can only be diagnosed with some booster pump troubleshooting.

Some common things that go wrong with the Polaris booster pump are bad mechanical pump seals, overheated suction and discharge fittings and leaks from the Polaris quick connect fittings. All of these problems can be fixed with a few replacement parts that are available online or from your local swimming pool supply store that carries replacement Polaris booster pump parts.To avoid costly booster pump repairs you should always replace the small parts that are starting to show wear or damage right away. This means if you start to see your pump seal leaking, don’t wait until it gets so bad that you cannot run the pump.

Soon as you see it leak replace it. This goes for anything else you see going bad on the pump. If you feel that something is going to break or looks like its damaged, you will want to shut the pump off right away and fix the problem. Ignoring or “putting off” the problem with the pump will only let the problem become worse and that will usually cost you more money and time to do the repairs.

How To Change The Polaris Booster Pump Seal

The Polaris booster pump seal is located inside of the seal housing. You will have to remove the front of the pump to first access the impeller. Once you have the front of the volute off you will want to now remove the impeller. In order to remove the impeller you will have to grab the back of the motor shaft and then with your other hand you will want to twist the impeller counter clockwise spinning it until it spins completely from the motor shaft.

Now that you have the impeller off you will want to unbolt the seal housing from the frame of the motor. Once you remove the seal housing you can remove the seal base. This is just one part of the mechanical pump seal. The second part of the Polaris booster pump seal will be in the small shaft of the impeller. You will also want to remove this part from the base of the impeller, as you will be replacing both parts of the booster pump mechanical seal.

Once you have removed both the pump seal seat and the spring from the impeller you can replace both parts for the new replacement Polaris pump seal that you have bought. It’s always a good idea to put a tad of silicon on the outer rubber casing of the seal seat. This will hold the seat in place inside the seal housing and also safeguard the seal base from leaking. After you insert the seal base you can slip the other part of the mechanical seal onto the impeller. Now you can turn the impeller clockwise and thread it back onto the pump shaft until it’s tight. Once the Polaris pump impeller is tight you can re-assemble the rest of the Polaris pump as the pump seal has now been changed.

How To Repair Suction Leaks On The Booster Pump

The Polaris booster pump could have some suction leaks in a few common places. The most common places that the booster pump will draw air from is the suction fitting and the volute drain plug. To avoid any air being sucked into the Polaris pump you will want to make sure that you Teflon tape both he threads on the suction fitting and the Polaris pump drain plug.

How To Hook Up The Polaris Booster Pump

The Polaris booster pump can be piped directly into your swimming pools filter system using PVC pipe or it can be installed with saddle clamps that can be connected to the existing swimming pool plumbing. Either way there is only one correct way to hook up the Polaris booster pump.

There is two fitting on the booster pump. The fitting in the front of the pump is called the suction fitting. This fitting will get connected to the discharge side of the swimming pool fitting. This is very important, as you will need to feed the suction side of the Polaris pump with pool water from the filter system. That is why you need to hook it to the discharge side of the pool system. The second fitting or the second connection you will make is to connect the discharge side of the Polaris booster pump to the line that returns back to the pool or to a flexible line that will go to the pool. Whether the Polaris is hooked to the wall fitting in the pool or if its being feed from a flexible like from the top of the discharge side it is important to remember that the Polaris 360, 390 or the Polaris black max are pressure driven units.

How To Turn On The Booster Pump

The booster pump will run if the pool pump is running. This is a safe guard to make sure that the proper amount of water flow is going through the booster pump. As we explained above the Polaris pump needs water from the discharge side of the swimming pool pump so when the Polaris pump is wired by the electricians it should be wired to only come on when the pool filter and pump are running.

To turn on the booster pump you will want to first turn on your swimming pool pump and let it come to full prime. Once the swimming pool pump has been running for a few minutes you can either turn the booster pump timer switch or on use the manual switch that will be located somewhere near the filter system or the timer control panel. Some pools will have both the manual Polaris override power switch and the Polaris timer and some will just have one or the other. Depending on who built your swimming pool will depend on how they wired your Polaris pool cleaning system.

How To Set The Booster Pump Timer

If you have a timer on your Polaris swimming pool cleaner you will want to set it to go on 30 minutes after your pool filter timer comes on. You will want to have the Polaris cleaner shut off about 45 minutes before the filter system does.

To set the timer on the Polaris you first will have to locate the time box. Once you locate the time box you will want to open the timer cover door and inside you will see a dial and two-timer pins. These timer pins will each have a small setscrew in them that you can loosen by hand. One time pin will say off and one timer pin will say on. If you turn the setscrews to the left, which is counter-clockwise you can loosen them and then slide them on the dial to the correct time. Once you have the off and the on pin set you can switch the timer on and if its between those times and the pool filter system is running your Polaris will start working.

Popular Polaris Pump Troubleshooting Questions:

Question: “Does my Polaris Pump filter my pool?”

Answer: No, The swimming pool filter system actually filters the pool but the Polaris unit will pick up and bag the debris inside of the pool.

Question: “Where can I get my Polaris Pump repaired?”

Answer: Most pump or motor repair shops can repair the Polaris pump.

If you have another Polaris Pump question please ask below:

How do I post a picture?

I emailed the picture to info@wetheadmedia.com.

Hi Becky,

OK – I looked at the picture and here is what I would do,

1) Run the main pump and make sure it runs at full pressure (strong power at the returns)

2) Once the pump is running for a few minutes , THEN turn on the booster pump,

3) Give the booster pump a minute to push water to the pool ( leave polaris machine disconnected )

NORMALLY the booster pump should “boost” water to the fitting on the wall of the pool.

IF NOT,

Here are some things I would check:

1) Backwash the pool filter

2) That valve on the left there open that a tad while the filter is running and see if there is a lot of pressure, This is the “feed” to the Polaris.

If you have pressure at that valve and also have great pressure at the pool returns, then there could be something wrong with the “impeller” inside of the pump and at that point you can try to fix it yourself if your handy OR have a local pool store fix it,

My opinion is that either the filter is not providing enough water to the feed (This happens when the filter is clogged)

OR

The impeller has “spun” off of the shaft which is very common when booster pumps over heat or run out of water.

Let me know the above and I can tell you the next steps (If you are handy )

Joseph

Becky,

I do have one question about this picture:

What is the black arrow I added pointing to?

It looks like a valve or something, I cannot see that good from this angle:

Let me know

Joseph

Hi Joseph,

Thanks for your response — no problem about the delay. My motor looks like the picture in your response. Is the capacitor in the metal box on top of the motor? Any tricks for getting at it or is it pretty straightforward?

Keith

Hi Keith,

There will be two screws on that cover, Remove the screws and then you will see the capacitor.

If you have a meter or a local pool store, they can test the capacitor for you,

You can see how to test one here:

http://www.wikihow.com/Check-a-Start-Capacitor

Joseph

Here is how you can check the Capacitor:

Source:

http://forum.allaboutcircuits.com/showthread.php?t=5326

Hope This helps you’ll

Joseph

Hi Joseph,

I was able to test that capacitor with my multimeter, but I’m not sure of the results. When I connect it the meter swings to zero (actually it pegs), then slowly begins to move to infinity. However, it never quite makes it to infinity (but it gets very close). I also did another test that I saw mentioned in another forum (not a pool forum though). They suggested that if you connected the leads that normally connect to the capacitor, the motor should run normally (they said to only do this for a very short period of time or you would risk damaging the motor). I tried that and get the same hum from the motor but it doesn’t pump. (Actually I get the same hum whether the leads are connected or not — does this tell me anything?)

Any suggestions on what I should try next? I’m tempted to try to replace the capacitor anyway since it’s inexpensive relative to a new motor or pump? Would a pool store be likely to stock the capacitor or is there some other store (e.g., a motor repair shop) that might have it locally? I tried looking online and wasn’t confident that I could find an exact match.

Thank you very much for your time and effort on this. I’m still hopeful that you’re going to be able to help me solve my problem at a savings over getting my local pool store out here for it. But even if not, do you have a way to accept donations for your time helping people like me?

Keith

Hi Keith,

Here is what I would do at this point.

I would look for a local “Motor rewinding / repair shop”

I actually used to work in one when I was younger, that’s how I know so much about pumps / motors.

See if you just go down to a local “pool supply” they will want to just sell you supplies. NOT that there is anything wrong with a pool store but there is a huge difference between some “kid” trying to sell you a new motor VS a season motor rebuild mechanic. (usually an older guy with TONS of electric motor experience).

The “Pump shop” will also be able to test the capacitor and also check the motor windings for shorts which can happen if the motor is exposed to lots of water etc.

Most Electric motor / pump shops will usually also give you a free estimate and let you know “the deal” with the motor as well. (save your time).

If you give me your zip code, I will find a place in your area that does this kind of work (hopefully as its a dieing trade).

Let me know what you think,

Joseph

Hello –

I disconnected my polaris 380 and then reconected. There is now some sort of air leak as the water right by the wall fitting is cloudy and you can see where it emanates from. Checked the pump and no leaks. Any help is appreciated.

Thanks

Hi Doug,

The Polaris fitting that goes into the wall has o-rings on it, Chances are you “pinched” an o-ring when sticking the fitting back in the wall..

OR

You don’t have the fitting set all the way in and its not “locked into place” correctly.

You DO NOT have air in the line, What YOU ARE seeing is a connection that is leaking.

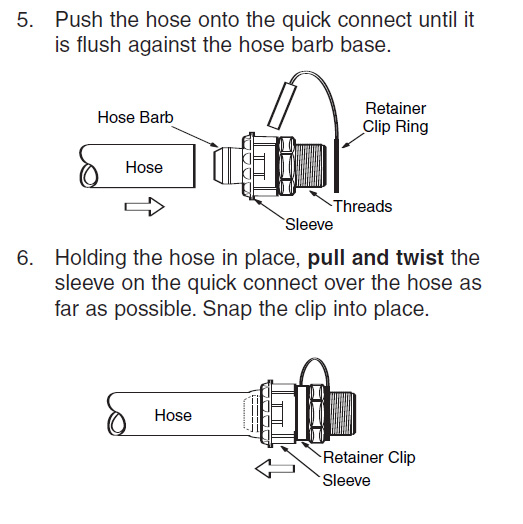

1) Pull the Polaris from the wall fitting,

2) Get some grease or lube ( Vaseline or Jacks Magic etc )

3) Lube the o-rings on the fitting

4) Push that fitting HARD into the wall socket and twist

That should fix your issue.

Let me know if you have any more problems or questions.

The above is “assuming” you have a Quick release system on the end of that Polaris hose.

Joseph

Hiya,

If anyone has a frozen motor, I just made this short little video on how to unfreeze a motor that is humming.

The video is a Hayward Super Pump but this could work with all motors,

Here is that video:

http://video.wetheadmedia.com/my-pool-pump-motor-is-humming

Now “sometimes†the bearings will be so frozen that this will not work, but its worth giving it “a whirl†VS shelling out $$$ for a new motor right away. I have been successful doing this many times for many customers over the years.

Hope this helps everyone even further.

Joseph

I am replacing a bad Booster pump, and swapping connections is easy, but I opened the panel to begin the rewiring, as it came with no cord, and the whole board is different! Adding an electrician bill is not in my budget, any more than the $300+ the pump cost. Suggestions ? When wiring, “guessing” is not an option!

Hi Tim,

Could you define: “panel”? Most booster pumps are wired with something called a “pigtail” in the electrical world.

The booster pump basically has three connections in that back of the motor. Two hots and a ground. These are also usually marked with a “a” and “b”.

When “I” swap Polaris motors in backyards, this is how “I” do it.(not saying you should do it, just explain how I do it)

1) Turn off the circuit breaker

2) Open the back of the old Polaris booster pump

3) Disconnect the “A” AND THE “B” terminals (usually a Flathead screw”

4) Disconnect the ground wire ( this will require nut driver)

5) Match the two wires that were on “A & B” TO the new motor

6) Reconnect the ground (screw is usually near top and also green)

7) close up the “wiring compartment”

8) Turn the breaker back on.

NOW: Please note that if your NOT comfortable with any of the above then the $300 for electrician may be worth it, although that sounds like a ridiculous rate as most electricians charge $75 – $100 an hour and this takes about 30 minutes..

Let me know if you have any other questions.

Tim,

Also:

http://www.electricmotorwarehouse.com/PDF/polaris_manual.pdf

Electrical Hook-up

The motor comes wired for 240 volts. The booster

pump motor may be wired for either 120 or 240

volts. To rewire, follow the instructions on the

name plate located on the back of the motor or

the “sizing†plate on the side of the motor.

A separate time clock (in addition to the filtration

system’s time clock) is recommended to control

the “On†and “Off†functions of the booster pump.

However, a manual on/off switch may be used.

If a time clock is used, it should be set to turn on

the cleaner at least one half hour after the pool

filtration pump is turned on and turn off the

cleaner at least one half hour before the filtration

pump shuts off. The Polaris will clean the pool in

three hours or less depending on the pool size

and the amount of debris. Periodically check the

time clock settings

My 1″ flexible supply line came loose from the booster pump. It took me about a week to get around to getting a new connection nut for the 1″ supply line. When I turned the pump back on it seemed to be about 3 times as loud as the filter pump. It is pumping water to the Polaris, but I noticed that the polaris was just getting hung up in corners, almost as if it does not have enough power. I cleaned the cartridge filter(which needed it) but it did not make the pump run any quieter or provide more power to the Polaris.

Is there a fix that i can make to the pump to quiet it down and increase power to the polaris.

Thanks in advance

Hi Tom,

Are you sure the Polaris Pump is not air bound? The noise your hearing could possibly be something called “cavitation” it happens when air and water mix, or it could be your motor bearings. I would shut the system and check the impeller and also bleed the Polaris pump free of air.

Joseph

Joseph,

Thanks for the reply. How do I bleed the pump of air? and how do i check the bearings.

Thanks

Tom

Thank you for your service. But I have some constructive criticism. When I picked up the shaft seal at my local electric motor repair shop, the owner warned me to be sure and run a bead of RTV between the front and rear of the pump before reassembling them. There was a sealant between the pieces of the pump when I disassembled it. If the sealant is required, it would be nice of you to include a comment in your instructions.

Hi David,

In the THIRD paragraph under “How To The Booster Pump Seal” it says:

” It’s always a good idea to put a tad of silicon on the outer rubber casing of the seal seat. This will hold the seat in place inside the seal housing and also safeguard the seal base from leaking. ”

Maybe you missed that when reading? Either way, Thanks for the feedback.

Let me know if you need any more help,

Joseph

I have replaced the seal, impeller, and o-ring on my PB4 booster pump. When I turn the pump on, it spins just enough to make the impeller so tight I almost cannot get it off and then the shaft freezes up. If I take the impeller and outer seal off, the pump will rotate just fine. What would cause the shaft to freeze up like that? Thanks for any help or advice.

Larry